Quality assurance measurements ensure that the machine generates just as much X-ray as needed to keep radiation exposure as low as possible to achieve good quality imaging and avoid repeated procedures. Quality assurance testing is done for the safety of both patients and staff. It also enables predictive maintenance, and can help extend the lifetime of the machine.

Computed tomography (CT) is a medical radiology imaging technique to get detailed images of the body for diagnostic purposes to discover a disease or injury.

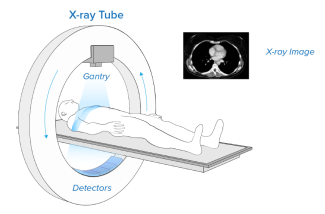

CT scanners use an X-ray source that rotates around the circular opening (gantry). During a CT scan, the patient lies on a bed that slowly moves through the gantry while the X-ray tube rotates around the patient, shooting narrow beams of X-rays through the body at different angles.

CT scanners use multiple digital X-ray detectors, which are located in the gantry across the x-ray source. As the X-rays leave the patient, they are picked up by the detectors. One can get either 2D cross-sectional images at various angles or a 3D image of the patient that shows the skeleton, organs, and tissues as well as any abnormalities. The tomographic image can be viewed on a computer monitor, printed or transferred to electronic media for further processing.

How to perform quality assurance testing

Different practices apply depending on professional role (medical physicist/service engineer), where you work (hospital/service organization/manufacturer), and geography.

Typical example of common measurements

Dose, kVp, time, beam width, and sometimes Half Value Layer (HVL). Dose Length Product (DLP) and Computed Tomography Dose Index (CTDI) values are calculated from dose measurements. This requires a CT sensor, and a CTDI phantom.

A physicist may in addition perform constancy testing, and check mAs/dose linearity. A service engineer may check mAs invasively on the machine.

|

Supported parameters

|

Additional options

|

Measure with RaySafe X2 CT sensor

Turn on Base Unit, and connect the sensor.

- Push the connected sensor into the

phantom or use the flexi stand for

positioning free in air - Expose

- Read result from Base Unit

For comprehensive analysis use the RaySafe View software.

Watch webinar:

Measurements for CTDI calculation

Watch video:

How to measure CT Dose Index (CTDI) of the CT scanner using the RaySafe X2 CT Sensor

Watch how-to-video:

Measuring with the RaySafe X2 CT Sensor

Download resources:

RaySafe Specification Brochure

X-ray Test Equipment Product Catalog

Case Study: Unilabs Performs X-ray QA Testing for Radiation Safety

Application Note: Measuring CT beam width with RaySafe X2

Flyer: Why do quality assurance testing of X-ray equipment?

White Paper: Why it is important to perform quality assurance testing for diagnostic X-ray

Suitable products for measurements on CT machines

Best practices for quality assurance testing

Quality assurance testing should be done according to local guidelines, national or international recognized standards, and manufacturer recommendations. Some example of standards are AAPM (the US), IEC 60601-2-43 to IEC 60601-2-65, 61223-2 (constancy testing), and 61223-3 (acceptance testing).

A phantom should be used to simulate the body of a patient and the scattered radiation during a diagnostic procedure. However it is possible to measure with the sensor free in air and use correction factors based on a previous reference measurement with a phantom.

For CTDI calculations, you can use the supporting RaySafe Excel template.

The history of computed tomography

The history of computed tomography dates back to 1917 and the invention of a mathematical theory by Johann Radon.

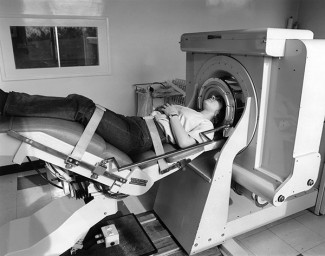

In 1961, UCLA neurologist William Oldendorf built a prototype in which an X-ray source and a mechanically coupled detector rotated around the object to be imaged. In October 1963, Oldendorf received a U.S. patent for a “radiant energy apparatus for investigating selected areas of interior objects obscured by dense materia”.

The first commercially viable CT scanner was invented by Sir Godfrey Hounsfield, United Kingdom, at EMI Central Research Laboratories. The first patient brain scan with this EMI-scanner was done on 1 October 1971.

And yes, it has been claimed that revenues from the sales of The Beatles records in the 1960s helped fund the development of the first CT scanner. Hence the name. More or less at the same time, Allan McLeod Cormack independently invented a similar process, and both Hounsfield and Cormack shared the 1979 Nobel Prize in Medicine.

Conventional focal plane tomography remained a pillar of radiologic diagnostics until the late 1970s, when usage of minicomputers and transverse axial scanning became common.